BT-Maric Constant Flow Valves save water and make products and processes more efficient – by always providing the chosen specified flow rate. The many unique features make the valves suitable for a variety of applications.

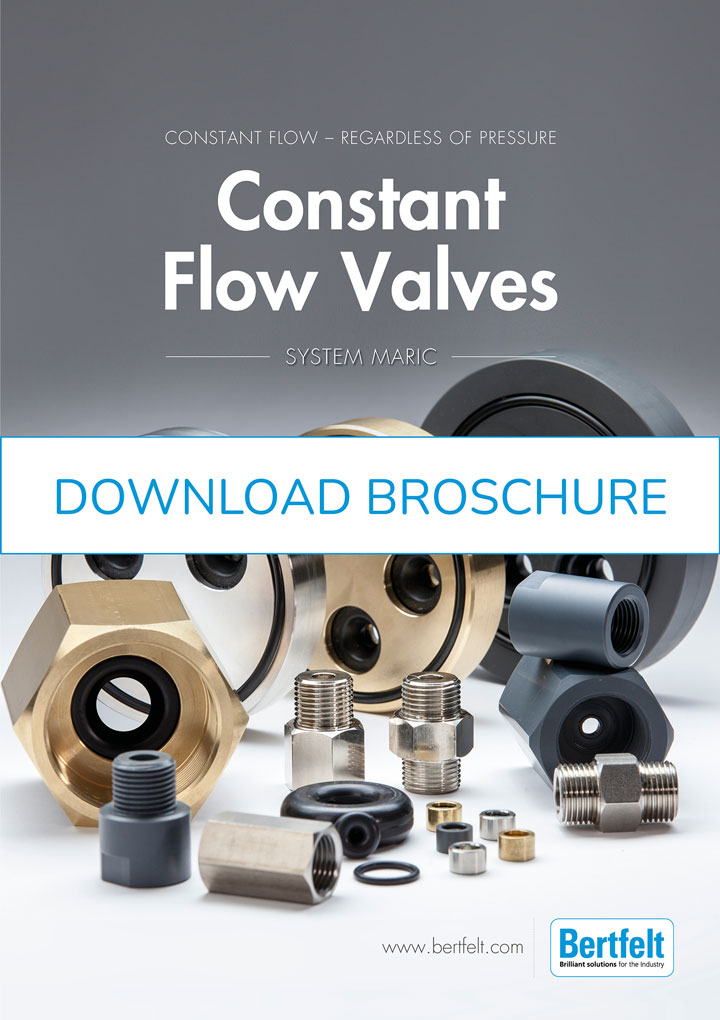

Standard connections

The BT-Maric Constant Flow Valves are available

in 3 standard connections:

Easy to install

Threaded constant

flow valves

BT-Maric Threaded Constant Flow Valves are designed for pipes from 1/8″ up to 2″ and regulate flow rate from as low as 0,15 L/min up to 342 L/min.

Cost effective and compact!

Constant flow valve

type Inserts

BT-Maric Inserts are designed to be fitted inside existing pipe work or other equipments. They control flow rates up to 233 L/min.

For larger flow rates!

Constant flow valve

type Wafers

BT-Maric Wafers are designed to be placed between flanges for pipe sizes between DN20 up to DN300. They control flow rates up to 8.854 L/min.

Do you need a constant preset flow rate in your application?

BT Maric Constant Flow Valve is made of a flexible rubber control O-ring, with an orifice diameter that responds instantly to pressure fluctuations within your system /installation.

Any questions?

Contact us today for more information about our standard or Tailor-made OEM solution.

Many applications, one solution

BT-Maric Constant Flow Regulators are designed to your flow rate specification and deliver a pre-set (non-adjustable) flow rate, that automatically controls the flow of water in a pipe – irrespective of varying pressure differential.

The most common applications are:

Industrial

- Dosage systems – usually together with a magnetic valve for easy control of fluid mixing.

- Industrial (washing) processes – precise control of chemical mixtures.

- Mechanical seals – constant flow valves are used to regulate water flows to pump gaskets and to regulate water flows in bore holes.

- Cooling systems – ensure the correct amount of fluid in the system.

Water treatment

- Water treatment & filtration equipment – creates optimum return flows to prevent damaging sensitive filters.

Water autorities

- Municipal waterworks & water authorities

– limit maximum water tapping to allow better dimensioning of systems.

– improve efficiency and reduce waste.

Irrigation and farming

- Watering installations in irrigation and farming projects – ensure optimum fluid flow at all outlet points.

- Animal farms – correct and limited flow to all animal stalls.

Project market

- District heating distribution – creates optimum return flows to ensure minimum flow during summer period.

- Commercial facilities – hotels, restaurants, condominiums, event area.

– shower, sinks, toilets, drinking fountains; reducing excessive water usage. - Humidifiers – ensure the correct fluid flow in the system.

Pump protection

- Mining and wellpoint installation – gland water flow control to gland-packing/stuffing box and mechanical seals of centrifugal and slurry pumps.

- Machines and plants

– ensure that an operator cannot wrongly adjust the fluid flow by mistake.

– ensure the correct amount of fluid to machines in export countries where water pressures could vary.

Hans Bodin, Managing Director of Åkab System, has been using BT-Maric Constant Flow Valves for many years in process equipment for the Swedish Food Industry.

Mr Bodin says that “In all projects we make sure to streamline and find resource-saving solutions when it comes to water and energy. In many of these projects, Constant Flow Valves are used to limit water consumption”.

Hans Bodin / Åkab System.